𝗗𝗼𝗲𝘀 𝘆𝗼𝘂𝗿 𝗰𝗼𝗺𝗽𝗼𝗻𝗲𝗻𝘁 𝘀𝗵𝗼𝘄 𝘀𝗶𝗴𝗻𝘀 𝗼𝗳 𝗶𝗺𝗽𝗮𝗰𝘁, 𝘀𝗰𝗿𝗮𝘁𝗰𝗵𝗲𝘀, 𝗼𝗿 𝘄𝗲𝗮𝗿 𝗺𝗮𝗿𝗸𝘀 𝗮𝗻𝗱 𝗻𝗲𝗲𝗱 𝘁𝗼 𝗯𝗲 𝗿𝗲-𝗰𝗵𝗿𝗼𝗺𝗲𝗱?

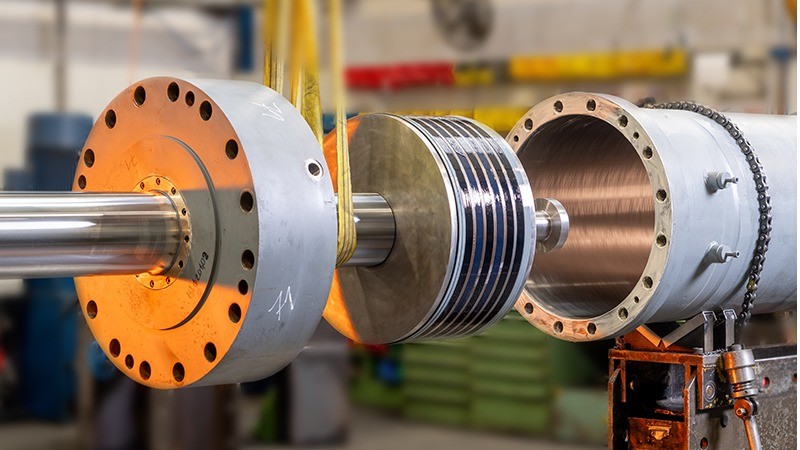

For around 100 years, Schenker Hydraulik AG has been the specialist for hard chrome plating and grinding of cylindrical parts. At our own hard chrome plating plant in Switzerland, we carry out repair chrome plating and new chrome plating, including grinding work. We also offer nickel-chrome coatings. This coating ensures comprehensive corrosion protection on all sides.

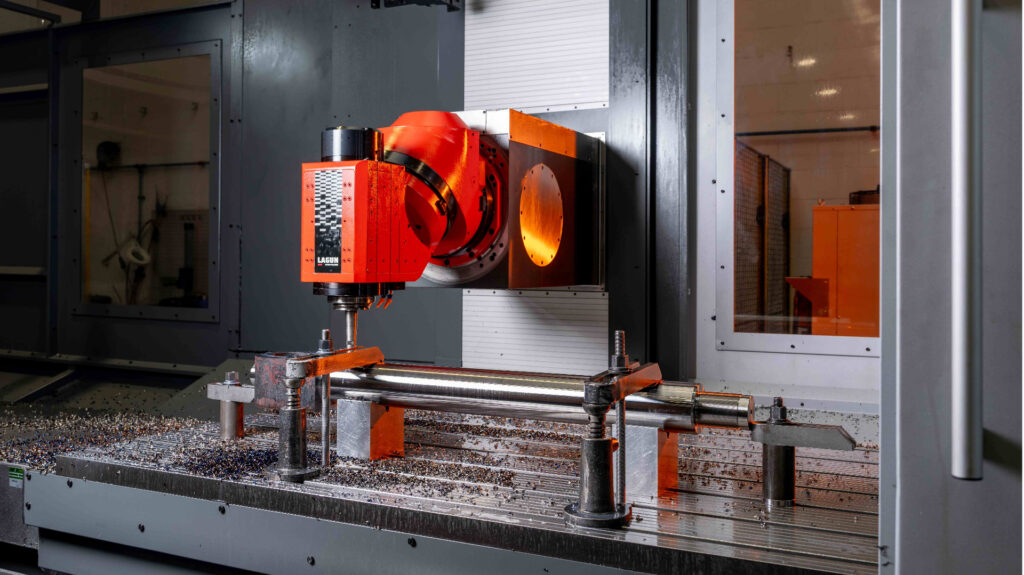

𝗥𝗲𝗽𝗮𝗶𝗿 𝗵𝗮𝗿𝗱 𝗰𝗵𝗿𝗼𝗺𝗲 𝗽𝗹𝗮𝘁𝗶𝗻𝗴 / 𝗱𝗶𝗺𝗲𝗻𝘀𝗶𝗼𝗻𝗮𝗹 𝗰𝗵𝗿𝗼𝗺𝗲 𝗽𝗹𝗮𝘁𝗶𝗻𝗴

Parts with damaged surfaces or dimensional deviations are pre-ground, hard chrome plated (to oversize) and ground back to size. This provides new, optimal protection and is a more cost-effective alternative to purchasing new parts. A layer thickness of 20 μm – 30 μm is usually sufficient to utilize the properties of the chrome layer. However, layer thicknesses of several 100 μm are also possible, usually in conjunction with dimensional corrections.

𝗘𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆: Express repair chrome plating.

𝗙𝗹𝗲𝘅𝗶𝗯𝗹𝗲: We process small and large parts up to Ø 550 x 8,000 mm.

𝗞𝗻𝗼𝘄-𝗵𝗼𝘄: We are experts in nickel-chrome coatings.

𝗖𝗼𝗺𝗽𝗲𝘁𝗲𝗻𝗰𝗲: We have many years of experience and certified processes.