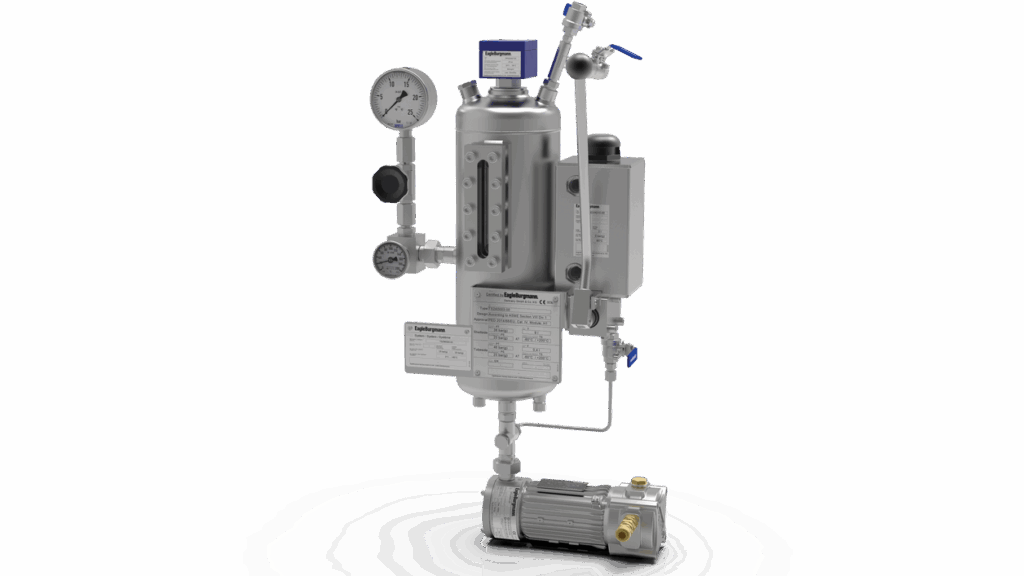

Features

– Successor of product lines TS2000, TS1020

– For ANSI pumps in chemical applications

– Pressure rating up to 25 bar(g) (362 psi)

– 40 % increased working volume compared to previous version

– Sight glass for level monitoring

– Cooling coil is supplied as standard

– All necessary system connections and brackets are provided as standard for optional components

– Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A

Advantages

– Improved heat dissipation

– Material of construction 316/316L – 1.4401/1.4404 stainless steel; sight glass made of borosilicate glass

– Modular system design, many pre-configured variants available

– Sleeves with recessed gasket prevent contamination of circuit by thread sealant

Standards and approvals

– ASME VIII, Div. 1 (Design, calculation and production)

– PED 2014/68/EU (optional)

– SELO, TR CU on request

– Compliant to TA Luft (German Clean Air Act)

Recommended applications

– Chemical industry

– Petrochemical industry

– Oil and gas industry

– Refining technology

Functional description

The TS system performs all the basic functions of a buffer/barrier system for dual seal operation:

– Pressure-build-up in the seal chamber

– Leakage compensation

– Circulation of the buffer/barrier fluid by thermosiphon effect or forced circulation

– Cooling of the seal

– Selective absorption of product leakage and prevention of dry running (tandem arrangement). When pressurized, this is provided via compressed air or nitrogen.

1) Design data, permissible working values depend on the operation conditions.

2) Low Flow: 8 l/min (process fluid), 10 l/min (cooling water), △T = 40 K

3) High Flow: 15 l/min (process fluid), 20 l/min (cooling water), △T = 40 K